Engineering plastics for over 55 years & counting

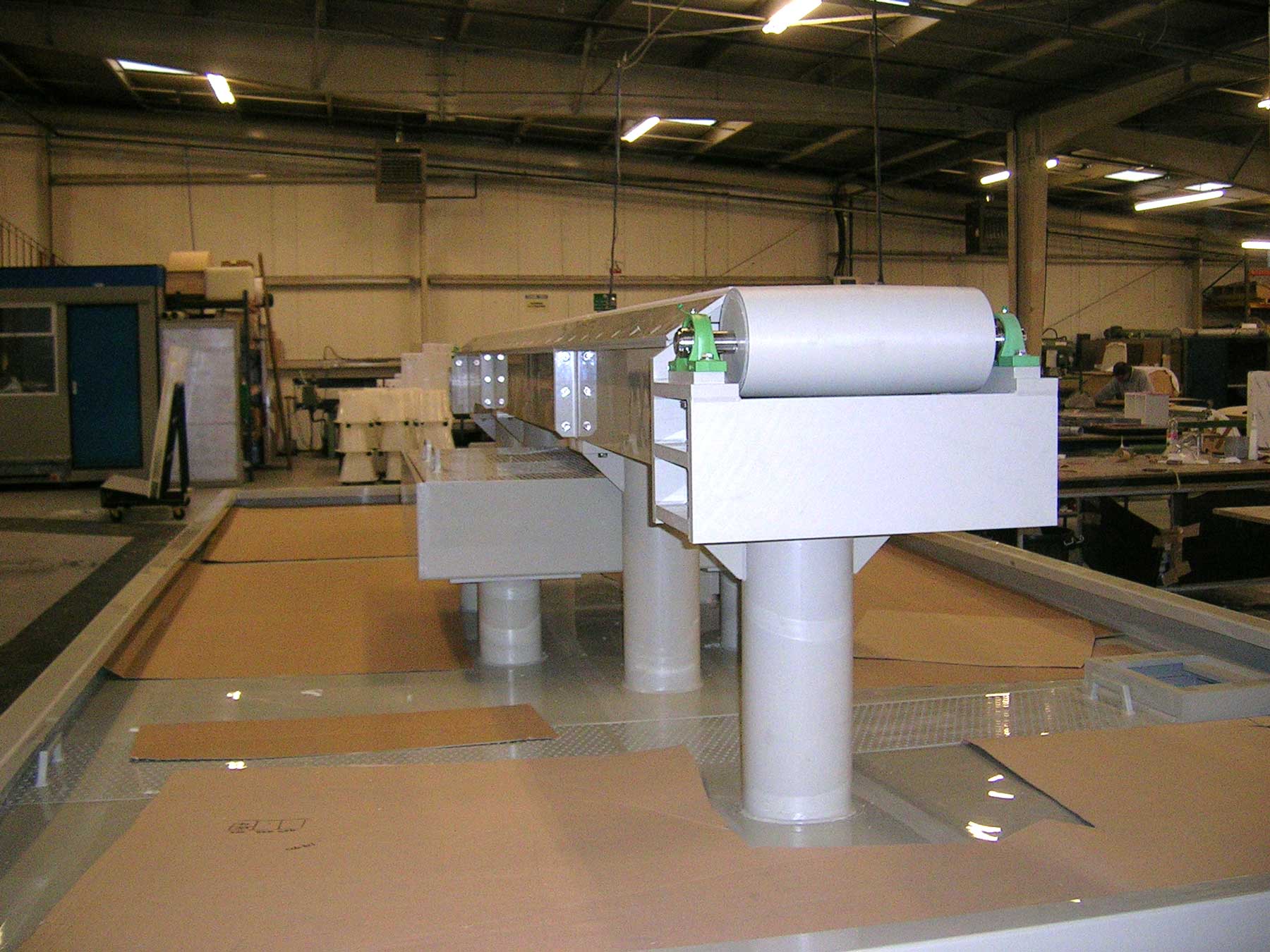

Barkston is one of the UK’s premier plastic engineering companies serving OEMs in virtually every industry.

When your business has challenging demands for equipment and uninterrupted operations, Barkston can help.

Our plastic engineered components and parts are powerful alone – but they’re even better in your operation.

We’re experts in plastic fabrication with over 55 years’ heritage in the UK and are fully committed to helping you gain a competitive advantage in your industry.

Innovative Thinking

Innovative thinking

We help customers worldwide to address component failure, improve speed to market, reduce maintenance, disruption, downtime and improve productivity.

We make better value, robust, resistant, more durable, re-usable components and products with outstanding strength to weight ratios suitable for even the harshest conditions.

Plastic engineering

We deliver bespoke excellent quality on time, so you can too. We develop appropriate engineered plastic parts and solutions that will contribute to the success of your business.

We offer on-site visits to help with requirements, problem solve, measure and understand how you work. We understand you are driven by your customer requirements, so we are too

Our capabilities include

Quality Assured

Quality assured

The Barkston team consist of highly experienced and trained engineers working with plastics such as acrylic, ABS, Acetal, CPVC, Delrin, ECTFE, Haylar, Nylon, Polypropylene, PVDF and PVC-U in sheet, rod, bar tubing, extruded rod, welding rod and duct form.

We create with plastic to enable our customers to develop competitive advantages in their marketplaces. Our team are personal, agile and able to turn things around as quickly as our customers need. At the same time, we pride ourselves on doing things the right way.

They are supported by a level of investment in the latest technology and solid working structures that conform to ISO9001.

Working together

Whether it’s from a drawing, CAD file, sample or existing product, we can work with you to supply the component, part or product that you need in plastic.

Our focused team will work with you from ideas, assist with designs and manage them through the best engineering techniques.

Accuracy & Reliability

Accuracy & reliability

Quality, testing and reporting are an integrated part of our operation. Our facilities are UKAS accredited and all of our projects are carried out in accordance to ISO 9001: 2015.

Auditing procedures at key production stages check that the components and products delivered to our customers are accurate, safe, reliable and conform.

Operational checklist

See how we have helped others – you’ll be in good company

Contact a plastic specialist

Solve application challenges & get valuable technical advice, we’re here to help.

We’d love to show you how to design, buy and engineer optimal plastic parts to increase your productivity, reduce your maintenance, provide better customer service, or all of the above!

Here are a few ways to reach out to our plastic experts.

Talk with us

Send us your requirements

Latest news

Barkston Apprenticeships 2025

February was such a busy month for Barkston with National Apprenticeship Week and appearing at Leeds Apprenticeship Job Fair at First Direct Arena for the very

Recruitment News

Barkston now has a dedicated up-to-date Recruitment page for both the Leeds & Hebburn sites. Here you will find all the info you'll need and how to

3D Prototype Printing Service

The Plastic People are offering an exclusive 3D Prototype Printing Service for our customers. For prototyping and visualisation for small batch designs produced at a cost-competitive